Everything You Need to Know About Perforated Aluminium Sheets

With so many different options in aluminum sheets and perforated aluminum sheets, you might be wondering which one to use. Perforated aluminum sheets can save you time and energy, but it’s important to know what your exact needs are before making your purchase decision so you don’t end up paying more than you have to! This guide will tell you everything you need to know about perforated aluminum sheets, whether you’re using them in your home or at work.

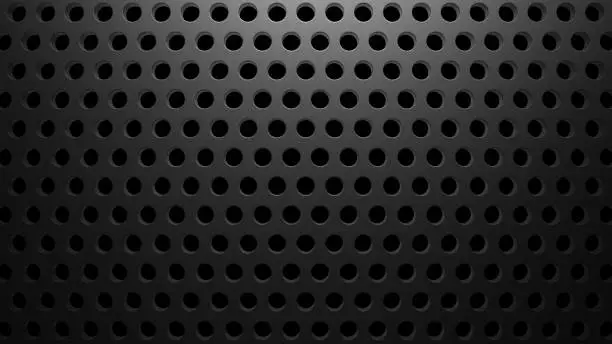

What Are Perforated Metal Sheets?

Perforated metal sheets are a type of perforated aluminum sheet that is a metal that can be cut or punched with small holes. This makes them perfect for filtration, ventilation, capturing dust and other substances, and many other purposes. There are many different types of metals that can be perforated as well, such as stainless steel or mild steel. This metal sheet can be used in the construction industry, food manufacturing industry, chemical production industry, and more.

How are perforated sheets used?

Perforated aluminum sheets are used in a variety of ways. The most common use is as an insulation product, as it can be easily installed on any surface and has the ability to keep heat or cool air in. It can also act as a protective barrier against noise, dust, rain, snow, sun, and wind.

If you’re considering installing perforated aluminum sheets on your home’s exterior, consider the following:

Determine how much of the wall needs insulation and then measure the space available on your exterior wall. Take into account that you’ll need at least 3 inches of clearance around all sides of your perforations for installation purposes.

Different varieties of perforated sheets

There are two kinds of perforated aluminum sheets: Type I and Type II. Type I is a thin sheet of metal with holes punched in it that is used for screening, ventilation, or as a roofing panel, while Type II has heavier gauge metal than Type I but has the same kind of perforations. They are both available in different gauges depending on the use you need them for.

Perforated aluminum sheets are widely used in building construction and architecture because they can be cut easily into desired shapes and sizes. With their lightweight design, these sheets can be installed quickly and easily without the need for any special tools or equipment. This means that perforated aluminum sheets require minimal labor costs during installation and offer a quick turnaround time on projects.

What are the health benefits of perforated sheets?

Perforated aluminum sheets can save you a lot of money on air conditioning or heating. The sheets are perforated with small holes that allow the hot or cold air in and maintain your desired temperature. These holes have a smaller surface area so they don’t let as much heat escape as solid metal surfaces would, which reduces the amount of energy it takes to maintain the desired temperature.

Perforated aluminum sheets also work well in areas where it’s difficult for solar panels to generate enough power, such as an office building where little sunlight gets through. These sheets provide an alternative source of heat by capturing the sun’s rays and dispersing them into your space.

Is it safe to install perforated sheets?

Perforated aluminum sheets are a great alternative to other materials, such as vinyl. Unlike other material options, perforated aluminum sheets can be easily installed and removed, which makes them a great option for those who want a temporary or semi-permanent solution. It is also possible to change the perforations on the sheets if you would like them in different shapes or sizes. The installation of these sheets is quite simple and does not require any special tools or expertise. All you need is a level surface and your panels will be installed in no time!

Choose Between Stainless Steel and Zinc Coated Steel

It is important to decide which type of metal will work best for your application. Stainless steel is durable, easy to maintain, and has a classic look. Zinc-coated steel is rust-resistant and comes in a variety of colors. The downside is that it can be more difficult to clean, so regular maintenance may be required. However, if you are looking for a way to differentiate your design or incorporate color into the project, zinc-coated steel may be the better choice.

Apart from this, if you are interested to know more about Paper Custom Soap Boxes Made to Order then visit our Business category.