Interesting Information About Packing

What are Foam Inserts

As the name implies, foam inserts wrap around and fill packages. There are many kinds of packing foams that can be used to satisfy this requirement.

Foam inserts can also be found in laminate finishes, such as suede, leather, and many other combinations, as well as Self-adhesive back layers.

Select The Suitable Foam Inserts for Product Packaging

Choosing the highest high-quality foam material is vital to protect your belongings. Polyethylene foam is denser than other kinds of foam and gives a snug fit. Contrastingly ester foam is a soft texture but provides superior shock absorption. In short, you can:

Choose the PE (polyethylene) foam if you have to cut it down to fit the items you want to store. PE foam is typically used to store oversized objects that weigh a lot or objects which can withstand a particular amount of impact, like power drills. It is also available as solid and antistatic alternatives.

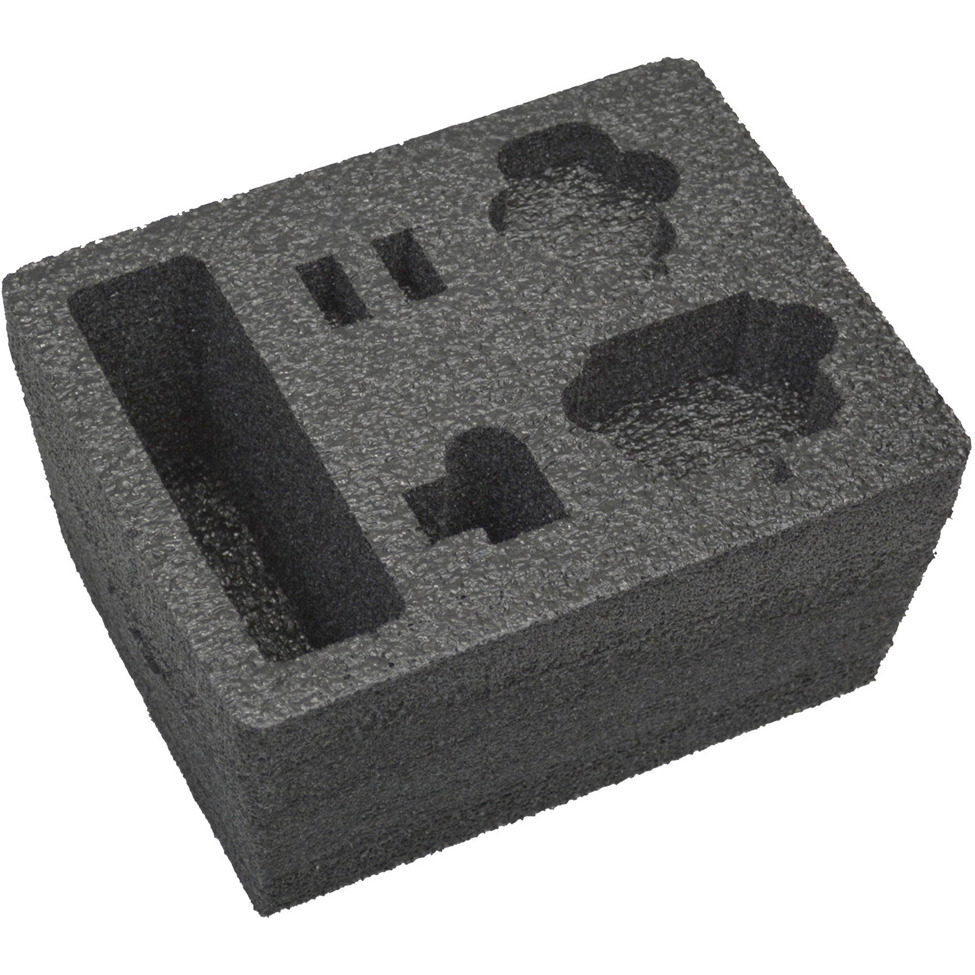

Select ester and polyurethane foam to protect more complex and irregularly shaped objects, such as cameras. The foam is soft and durable and can shield delicate things from minor collisions.

Foam Box Insert Options

It can be set up in many ways. The solid foam pads can be placed in the lower part of the box, creating one or two inches of cushioning. This can prevent objects from coming into contact. If the case is small, a solid pad could be utilized compared to more extensive patients, or you can use larger concrete pads to store larger objects.

The convoluted foam, often called egg cartons, works well for cases with thinner walls and is utilized to transport objects that cannot withstand any motion during transportation.

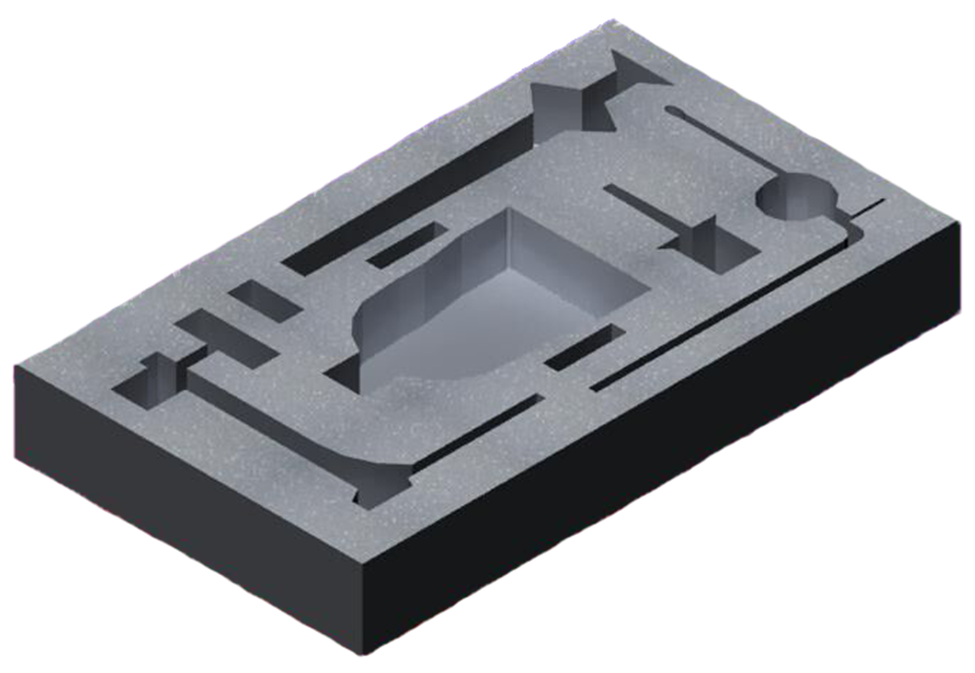

Another option to consider is a custom alternative to make custom box inserts. Most cases are “pick and pull” with an elongated base on the lower part. They are also able to be filled with removable cubes of polyurethane foam. Removing the cubes one by one for your items to fit is required to free up space.

Foam Insert Cutting Methods

Many state-of-the-art cutting methods permit you to make accurate, precise cuts through foams. These include:

Die Steel: These are designed to cut foam precisely and guarantee that your inserts are specifically made.

Wire Cutting: Wire Cutting with a computer is the programming of drawing CAD and AutoCAD. Customers may request drawings in CAD or design them according to specifications.

Digital Knife: cutting machines can make multiple foam inserts from a single sheet of foam.

A variety of options are offered. Various options are available for custom box foam inserts and pads. You can also create your designs using simple online tools. Foam inserts are an economical method to protect sensitive objects.

Production of Foam Inserts

Foam is utilized for a myriad of reasons in transport. It is perfect for holding delicate objects like bottles of medical equipment or even medical supplies. Cushions are the items to prevent injury that may result from an accident. The foam inserts are made to match the dimensions of any things you bring, so you’ll have the highest level of protection. How do you make foam-filled inserts unforgettable? Find out more about the process of making them and why they could be an excellent idea to put in product boxes.

The benefit of custom foam is that it can be made to match the measurements of the object it’s protecting. Knowing the type of foam, you should select is vital to ensure the safety of your items. Before you purchase foam packaging inserts, you must consider the products they protect, considering the impact of transport and the stress your workplace puts on the items you’re transporting.

Foam inserts are manufactured with a variety of substances, such as polyurethane as well as polyethylene. It can even be designed to decrease static. After the material is chosen and organized, it’s formed to fit the packaging products. These foam pieces are then placed inside the case and ready for use!

Why Foam Box Inserts Are Essentials?

Foam interiors are excellent because foam properties enable them to take virtually any shape you require. Due to its flexibility, foam inserts can be used to hold products in place until they can be manually removed.

It’s also shockproof, which means it can withstand the bumps of an airplane or car on rough seas during an excursion on a boat. Anything you store inside your custom box is secure if you’ve designed special foam inserts that protect the contents.

Foam interiors are also incredibly durable. They will last as long as required. To harm your foam interiors, you should be careful not to damage yourself by causing harm. The foam inserts can last longer than the container they’re placed in to shield them.

Apart from this, if you are interested to know more about Guide To Moving then visit our Business category.